Micromanufacturing and Microdispensing are a critical step that enables the operation of different technologies as lab-on-chip, microfluidic platforms, and microelectronics among others. The intervention of new equipment is critical to achieving this new exciting technology. The areas of science with increasing requirements on microdispensing technologies are material science and life science. The fast immersion of these techniques is changing the way of how nanomaterials are used on surface technologies like sensors, microarrays, and micro-reactors.

Micromanufacturing

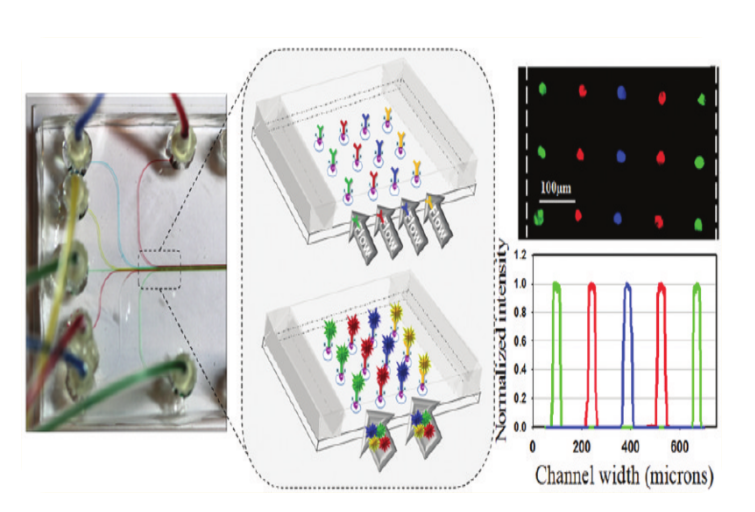

The micromanufacturing process inside of channels can be achieved by the application of two streams with laminar flow, through this approach the construction of microwires and patterning is easily achieved 3. Even more complex patterns are designed by multiple laminar flow streams, e.g., multiple protein patterns are obtained by the combination of specific biomarkers in different laminar flow streams. The designed consists of seven inlet branches at different positions, branches merge into the main microchannel branch; when the flow from the several branches enters into the interface, the flow produces different functionalized areas with three up to seven different antibodies. The patterns obtained by this approach are recognized as antibody microarrays which allow a high throughput immunoassay, this approach will allow the construction of different biomolecular pattering with aptamers, peptides, and proteins2.

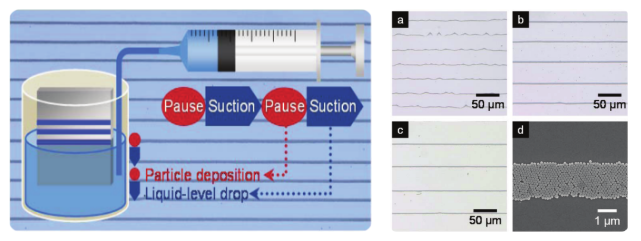

Syringe pump systems improved convective self-assembly; a synthesis method to obtain an association of particles join by non-covalent interactions. The way this is achieved with a fast liquid level control; colloidal silver dispersion is deposited by the lowered or raised of the liquid level (self-assembly occurs during the pause step). The technique allows the fabrication of stripe patterns; space and width are fully controlled by the implementation of the microfluidic syringe pump. The stripe patterns are in agreement with mathematical models developed for continuous film formation(Mino, Watanabe, & Miyahara, 2012). The advances with this type of microfabrication allow liquid-level manipulation is improved by microfluidic syringe pump selection and the establishment of a two-step procedure the fabrication of a large-scale grid network pattern composed of silver nanoparticles is achieved.

The final goal with micro manufacture systems assisted with syringe pumps is the direct writing methods. Gallium oxide has been deposited due to the fact it is a liquid metal 1. The methods described in this revision allow rapid and one-step fabrication to achieve uniform films; and could be implemented with nanoparticles, proteins, polymers among others. Shortly these techniques will facilitate the creation of novel designs for electronic, sensor, capacitor, and energy applications.

Microdispensing

Pattering control is fundamental in life science studies at a cellular level. Techniques as laminar flow are conjugated with a capillary system, the combination of laminar flow and capillary system to achieve cell culture patterns. The implementation of this technique by Takayama 1999 allows the microdispensing, delivery, and targeting of enzymatic reactions on cells, even better a portion of a cell can be targeted by this approach. A syringe pump could be implemented to produce a control surface with the attached cell; at the same time, microdispensing and enzymatic control are enabled (Takayama et al., 1999).

Microdispensing for cells has been studied for a long time. However, the microdispensing techniques are also implemented in new microfluidic bioreactor platforms which need to improve microdispensing variable control for different operations related to microfluidic bioreactor performance. The reactors are cleaning procedure, the microalgae culture layer establishment at 1-3 microliter/min, cleaning excessive algae 10-15 microliter/min, fresh culture media perfused at one microliter/min, perfusion of fluorescence indicator at five microliters/min. In this way, the authors can establish algae colonies, feed the reactors, and follow the oil production which is the main goal of the research4.

Microdispensing by the implementation of microfluidic is still in research. However, the potential applications and developments are quite promising. New work is needed to understand better the interaction of microfluidic systems like the bioreactors and cell patterns described above. Other applications that need microdispensing are small fuel cell devices and small batteries; these new equipment are new exciting energy technologies studied at a microliter on nanoliter level. Microdispensing technologies with microfluidic syringe pumps is a promising field with continuous progress in the years to come.

References

- Boley, J. W., White, E. L., Chiu, G. T. C., & Kramer, R. K. (2014). Direct writing of gallium-indium alloy for stretchable electronics. Advanced Functional Materials, 24(23), 3501–3507. https://doi.org/10.1002/adfm.201303220

- Didar, T. F., Foudeh, A. M., & Tabrizian, M. (2012). Patterning multiplex protein microarrays in a single microfluidic channel. Analytical Chemistry, 84(2), 1012–1018. https://doi.org/10.1021/ac2025877

- Kenis, P. J. (1999). Microfabrication Inside Capillaries Using Multiphase Laminar Flow Patterning. Science, 285(5424), 83–85. https://doi.org/10.1126/science.285.5424.83

- Kim, H. S., Weiss, T. L., Thapa, H. R., Devarenne, T. P., & Han, A. (2014). A microfluidic photobioreactor array demonstrating high-throughput screening for microalgal oil production. Lab on a Chip, 14(8), 1415. https://doi.org/10.1039/c3lc51396c