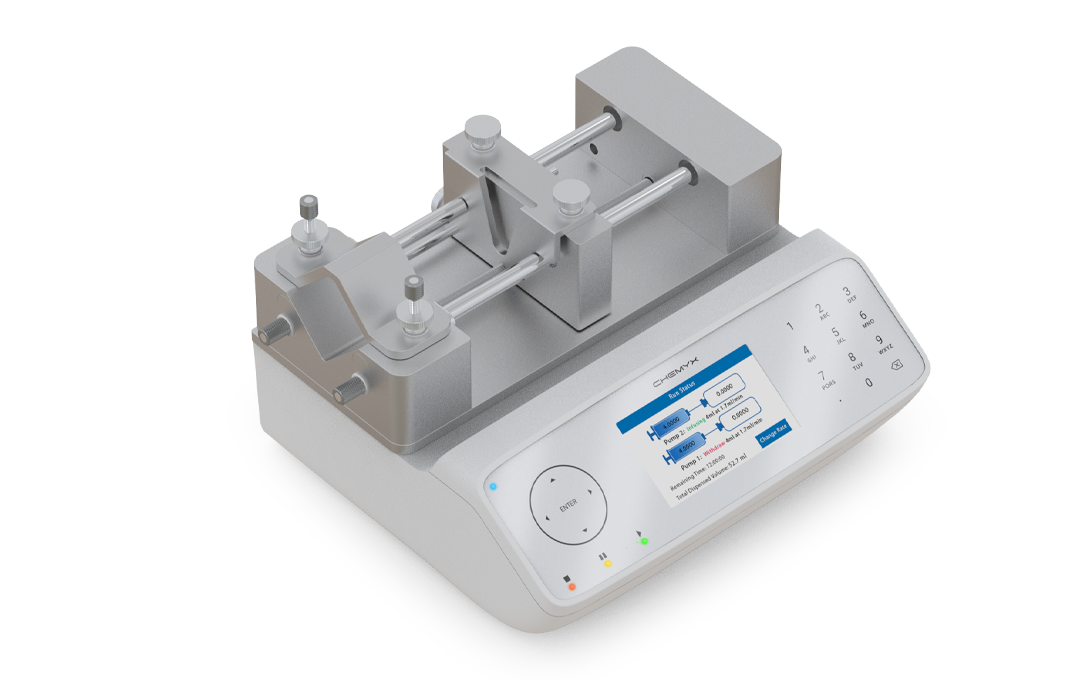

Fusion 6000X High Pressure Syringe Pump

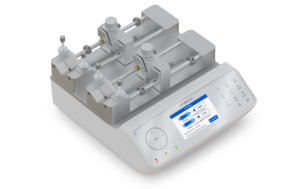

The Fusion 6000X high-pressure portable syringe pump is designed for dosing viscous solutions and semi-solid material against pressure with microfluidic pump precision.

The Fusion 6000X temperature control syringe pump has the following unique features:

- Portable syringe pump for high-pressure applications with 700 lbs. linear pushing force

- Priming buttons for easy syringe plunger adjustment

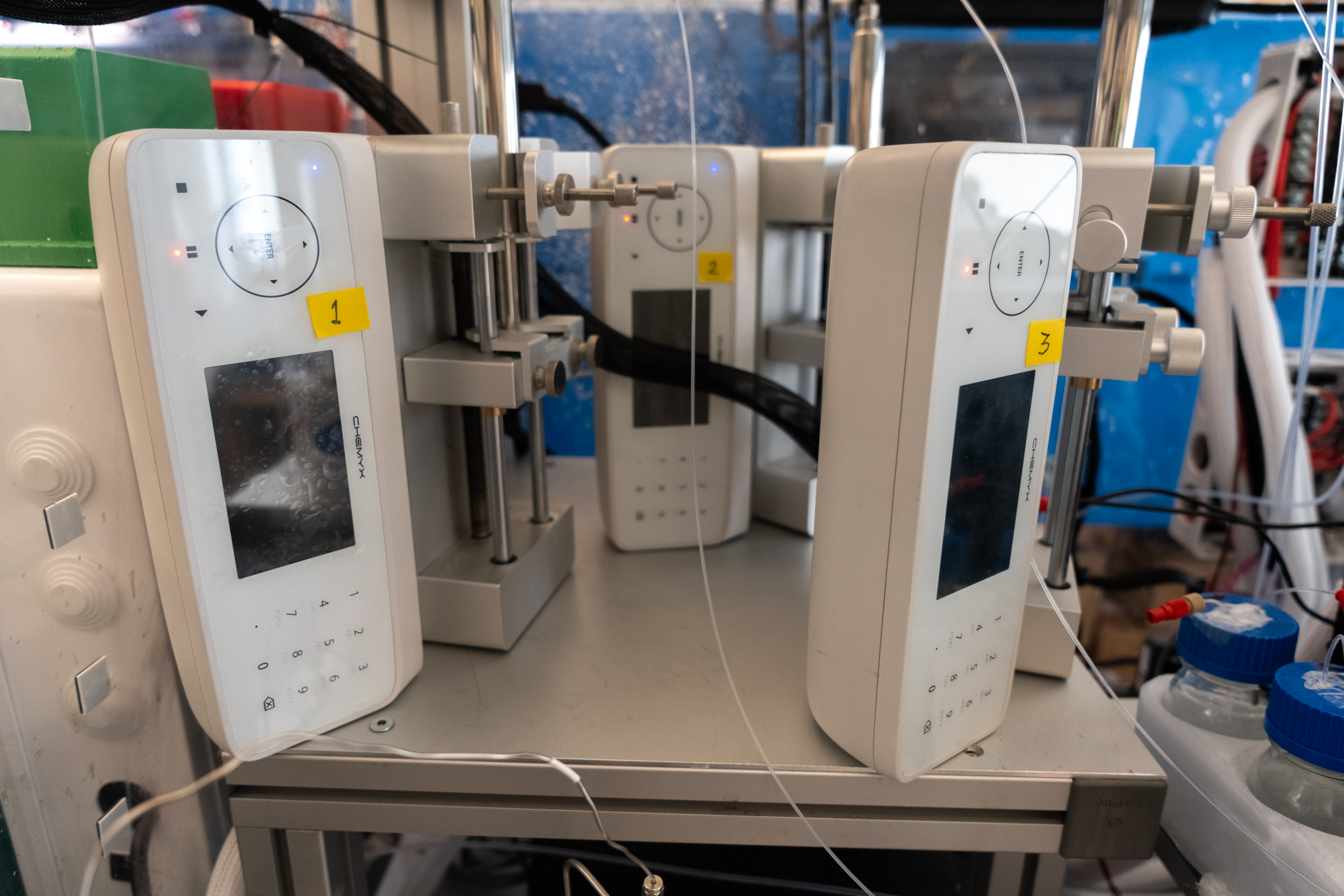

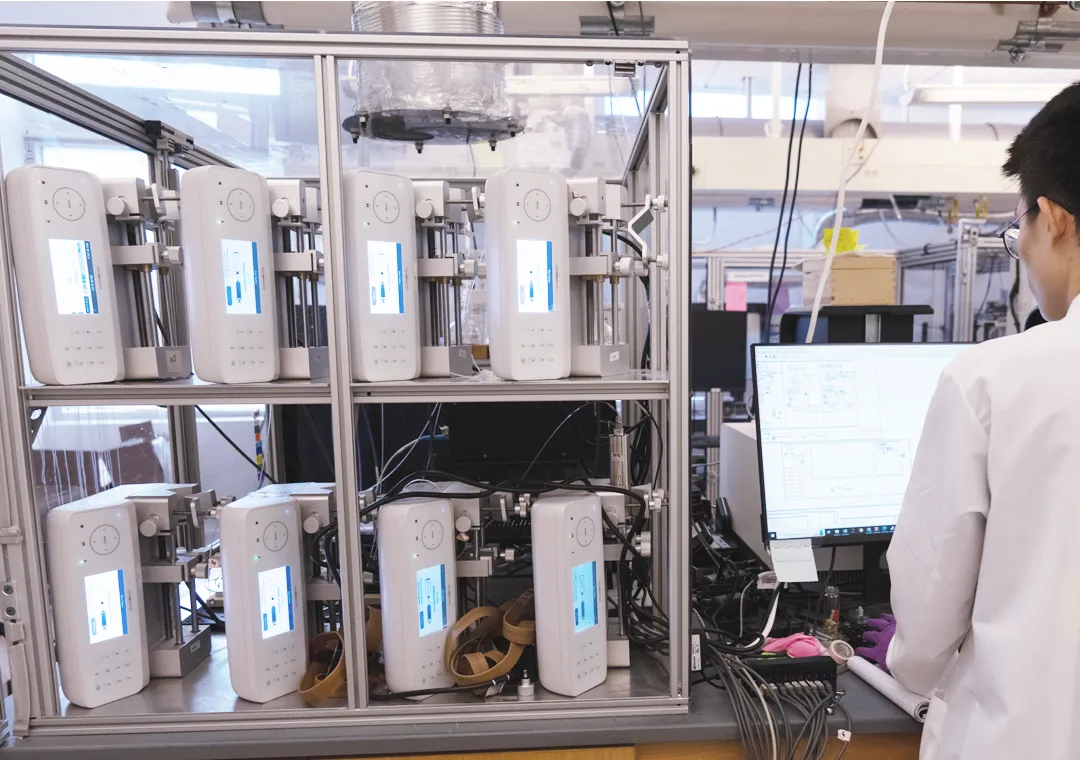

- Modular 4 syringe expansion pack to increase syringe capacity

- Add on a syringe heater to warm the contents of one syringe

- Add on a pressure sensor for pressure monitoring and control

The all-glass touch screen and heavy-duty mechanical structure, allow the Fusion 6000-X constant pressure syringe pump to be easy to clean and has high durability for industrial lab environments.

- Holds stainless-steel syringes from 5mL to 300mL

- Rates from 0.0001 mL/min to 408 mL/min

- Control via touchscreen, USB, RS232, TTL

- Free Programmable Mode Included

- 2-Year Limited* Warranty

- Available Accessories