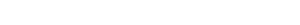

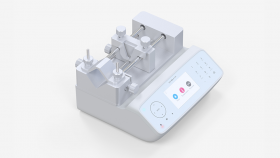

Fusion 6000 High Pressure

Syringe Pump

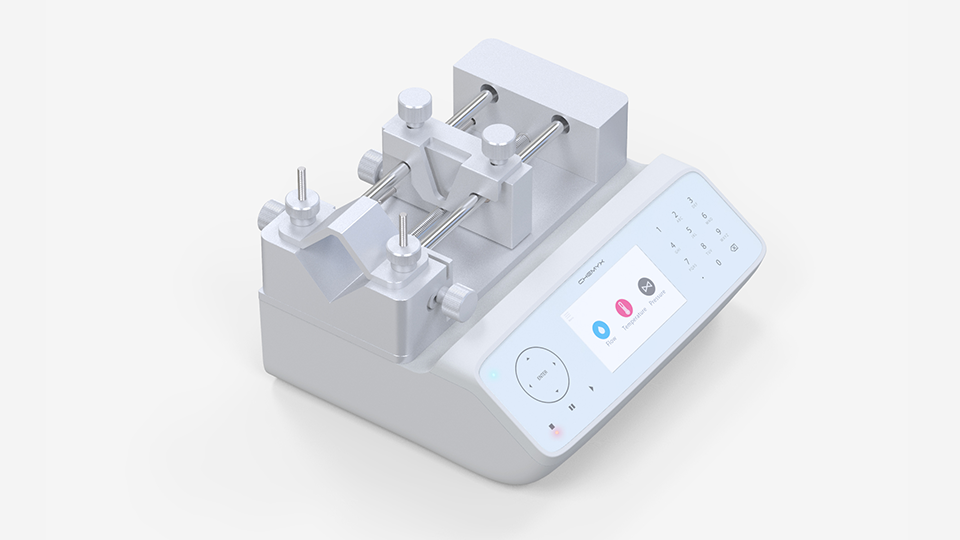

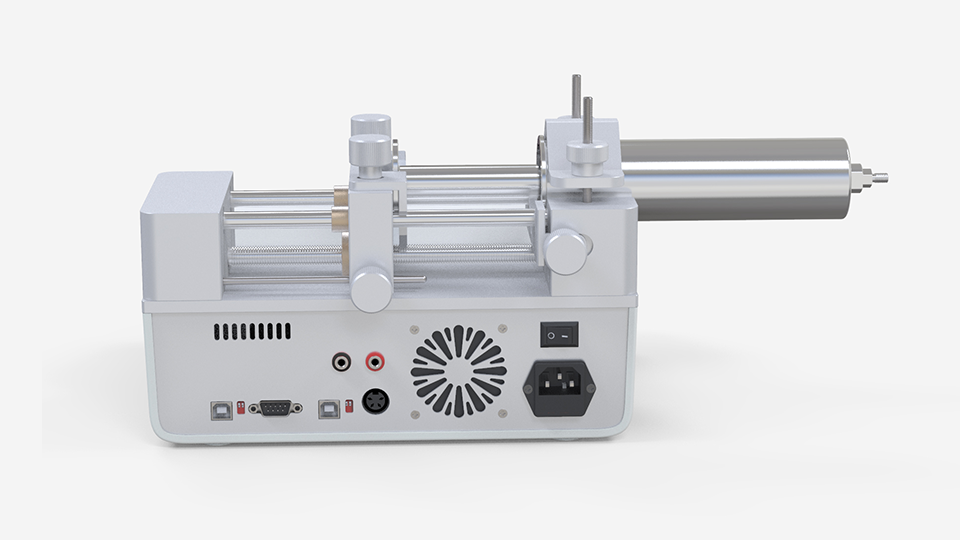

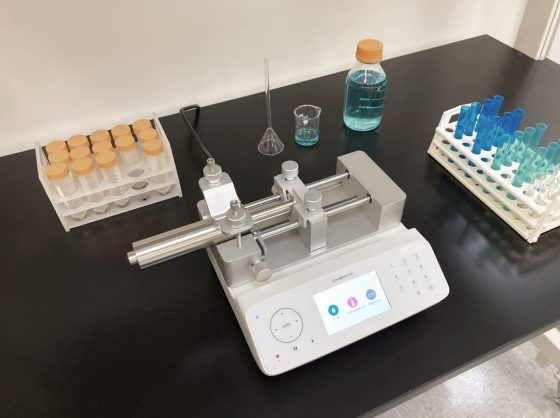

The Fusion 6000 high-pressure syringe pump is designed for dosing viscous solutions, and semi-solid material injections against pressure. This syringe dosing pump has the following unique features:500 lb linear pushing force, an add-on syringe heater, an add-on pressure sensor; an add-on 4 syringe rack. Those features allow Fusion 6000 to work against high back pressure; warm up the syringe, and monitor and control the pressure inside the syringe and increase the syringe numbers to four. With an all-glass touch screen interface and heavy-duty mechanical metal structure, Fusion 6000 syringe pumps are chemical resistant and have high durability for lab and industrial environments of all types. Backed by a Chemyx 2-year warranty, you can have the confidence of reliability and precision for years of service with this high-pressure pump.

- High-pressure applications

- Temperature and pressure control options

- Holds stainless-steel syringes from 5mL to 200mL

- Rates from 0.0001 mL/min to 271 mL/min

- Control via touchscreen, USB, RS232, TTL

- Free Programmable Mode Included

- 2-Year Limited* Warranty

- Available Accessories